AIAG

Home » AIAG

Function

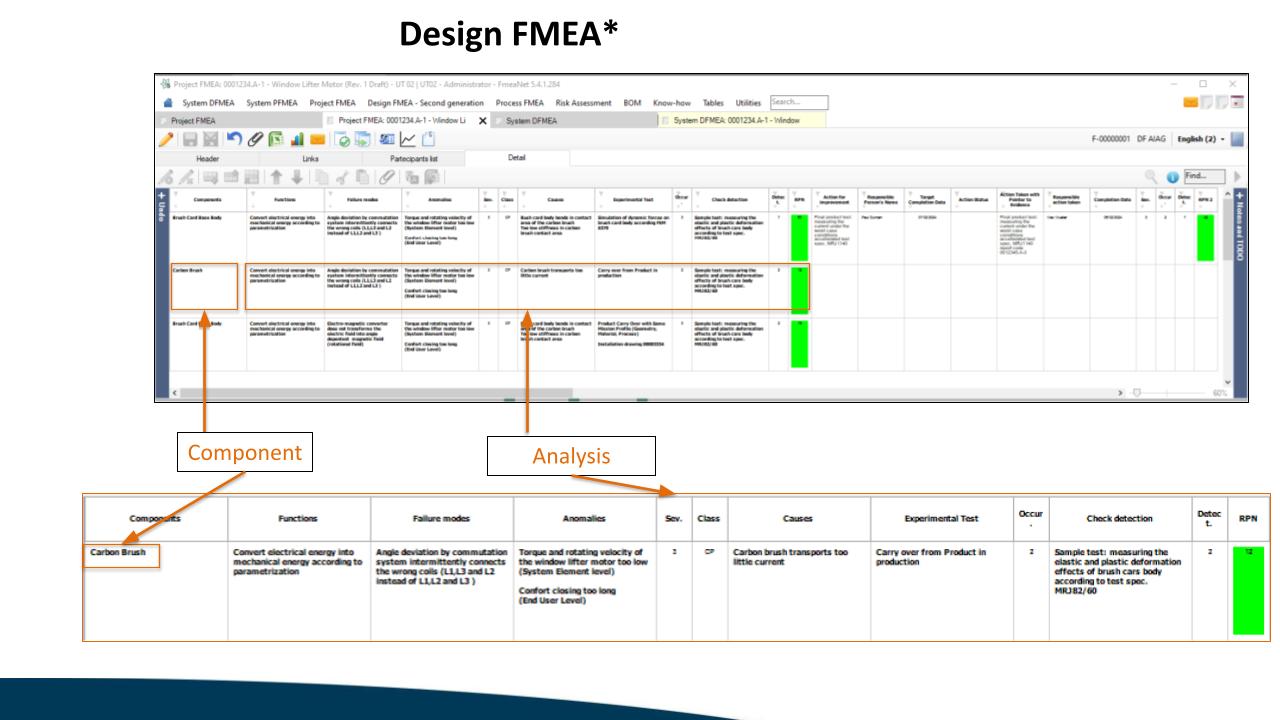

DFmea

Project Fmea analysis is used to highlight and correct any design weaknesses that may lead to failures, problems and malfunctions during the use/application of the product.

Function

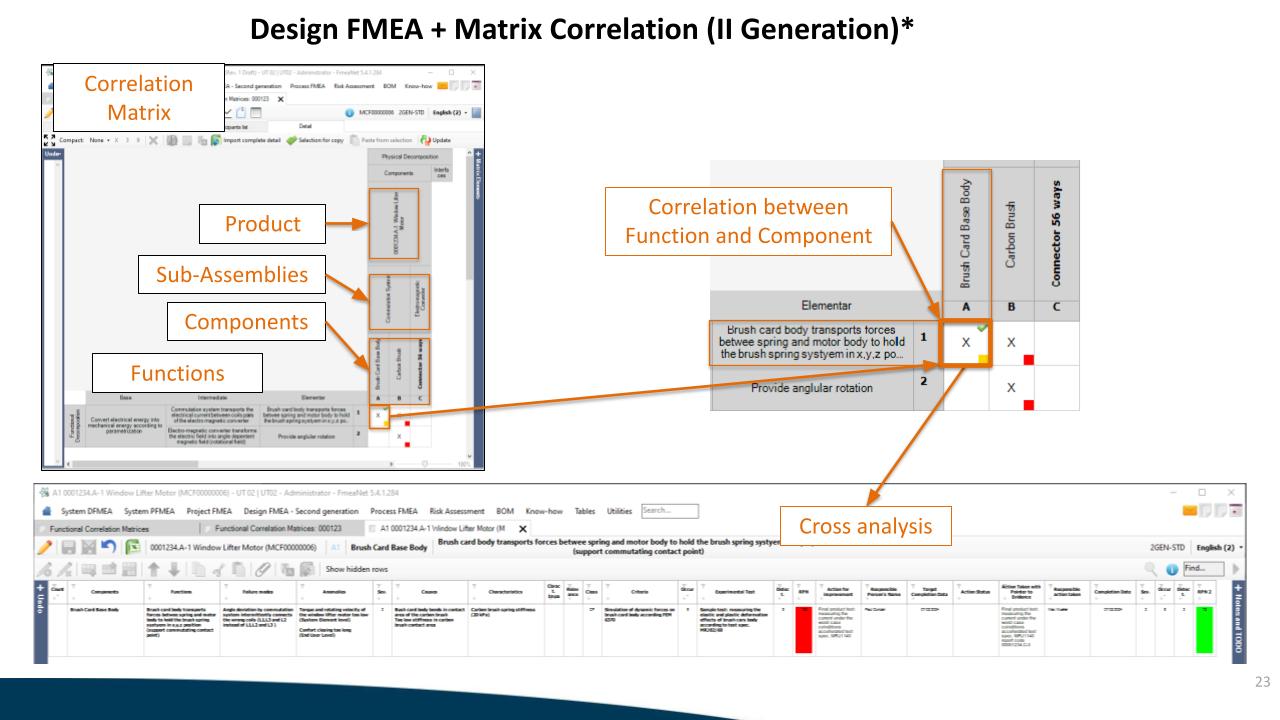

DFmea + Correlation Matrix (Generation II)

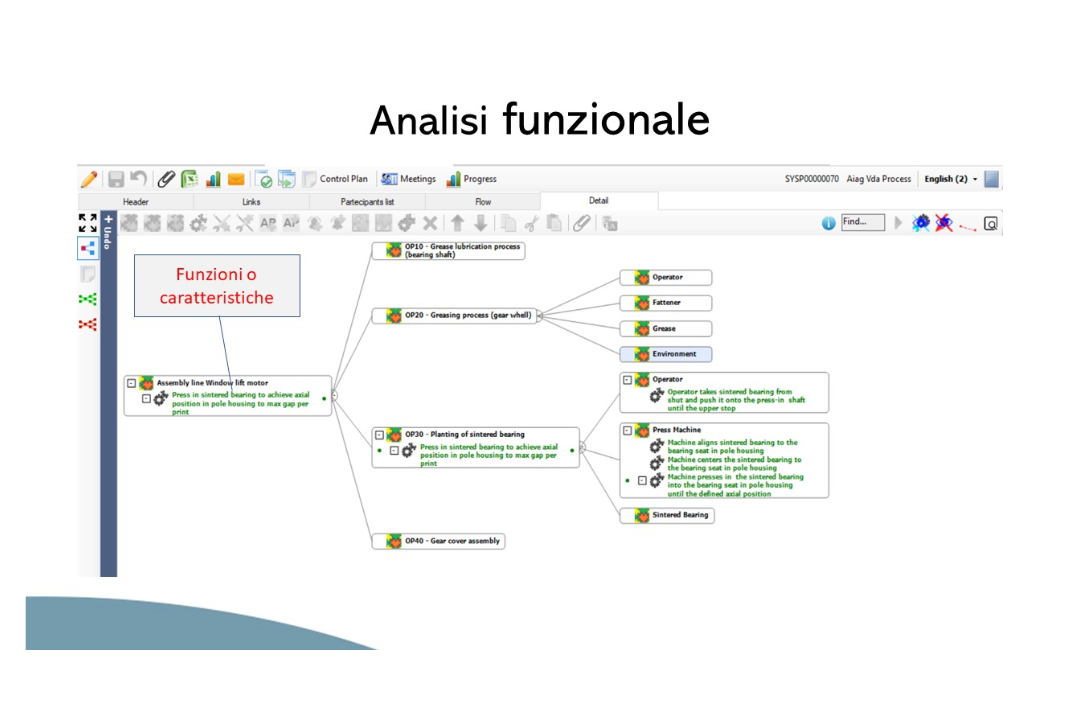

The first feature that distinguishes the second generation FMEA from the classic one is the emphasis placed on the functional approach in project analysis. In fact, a more complete and structured analysis activity is introduced in order to identify all the functions expected by the customer and to have a more organic vision of how the product in question will realise them: it is the starting point for the actual FMEA analysis. All this is intended not to lose the customer orientation, who must guide all stages of product development. The second generation FMEA becomes a technical memory tool, requiring the specification of the criteria used in the design phase to try to maximise customer needs. In addition, it takes on a normative character transforming itself into the Risk Matrix, which contains the design know-how, at the best state of the art available in the company.

Function

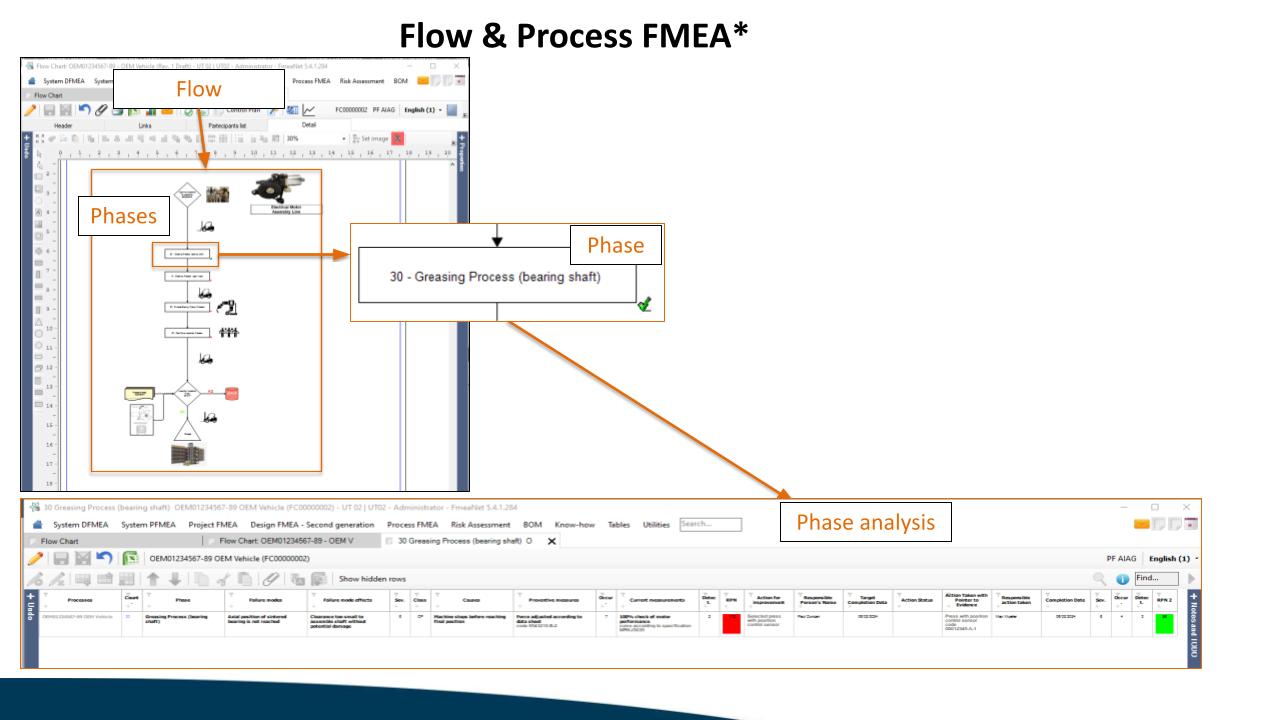

Flow & Process FMEA

FmeaNet is equipped with a tool for the graphic realization of the flow with the possibility of enriching the same with attachments, symbols ... The realization of the flow is fundamental and indispensable for the subsequent creation and drafting of the FMEA of Process.

Function

PFmea

Analyses the potential drawbacks of the product's own manufacturing/assembly process. The process FMEA is based on the assumption that the project has been correctly defined. For each phase foreseen on the Flow, the possible risks must be analysed by defining the Causes and Controls necessary to eliminate them. A Pfmea may be valid for different part numbers. PFmea are subject to process changes resulting from Lessons learned, customer complaints, new process implementations; it is therefore important to keep them up to date by carrying out the necessary maintenance. FmeaNet has a very effective tool to simplify this maintenance.

Function

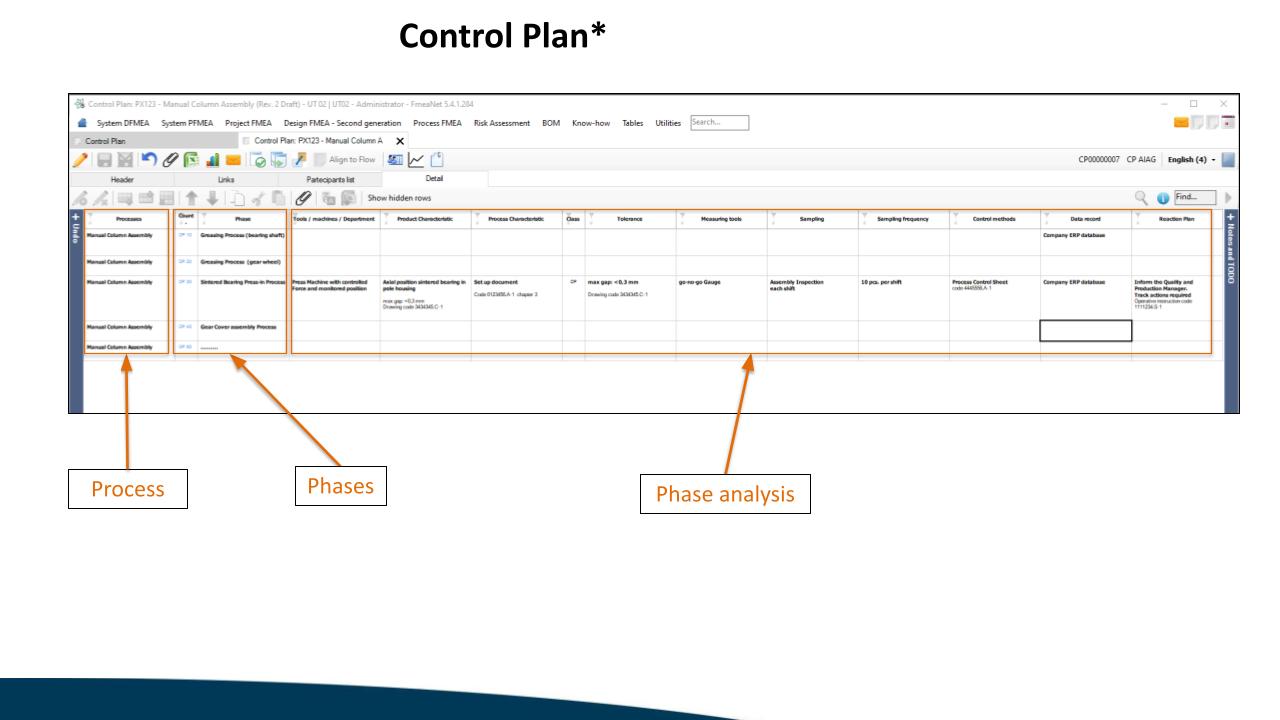

Control Plan

For each product, the critical and important characteristics represented on the design of the overall must be analysed. The analysis is formalised for each individual phase provided on the Flow considering the relative Pfmea. A Control Plan is specific to a single product code, as it considers the characteristics of the individual product. Flow-PFmea-Control Plan are three documents that need to be integrated with each other and it is critical to remember that changes made to one of the three must be reported in real time for possible review of the other two.

Our strengths

- Easy to use, thanks to edit in cell

- Managing contextual suggestions

- Powerful search tools

- Monitoring of know-how

- Integration and Alignment with Flow and Control Plan (PFmea)

- Management of masters at the phase level (PFmea ) or component level (Dfmea)

- Multilingual

- Multi-establishment

- Guidance and management of a shared methodology within the company

- Compliance with Industry Standards (AIAG, VDA, IATF 16949…)

- Management of navigable timelines, email alerts, statistics and dashboards

*Data as per Figure B1.8-2 DFMEA & Figure B2.8-2 PFMEA Failure Mode and Effects Analysis – FMEA Handbook First Edition Issued June 2019, 2nd Printing 2022 Copyright 2019

"Learn how to transform the

Management of the FMEA in a

Routine activities...

Request a demo of

FmeaNet!"